What is a Clean Bench?

A clean bench, also referred to as a laminar flow bench, is an essential piece of equipment designed to maintain a contamination-free environment. This apparatus operates by passing air through a high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filtration system. Once the air is filtered, it is directed over the work area in a uniform, laminar flow, ensuring that particulates are consistently swept away from the workspace. This controlled environment is crucial for protecting samples, processes, and materials from particulate contamination, ensuring sterility and precision in various tasks.

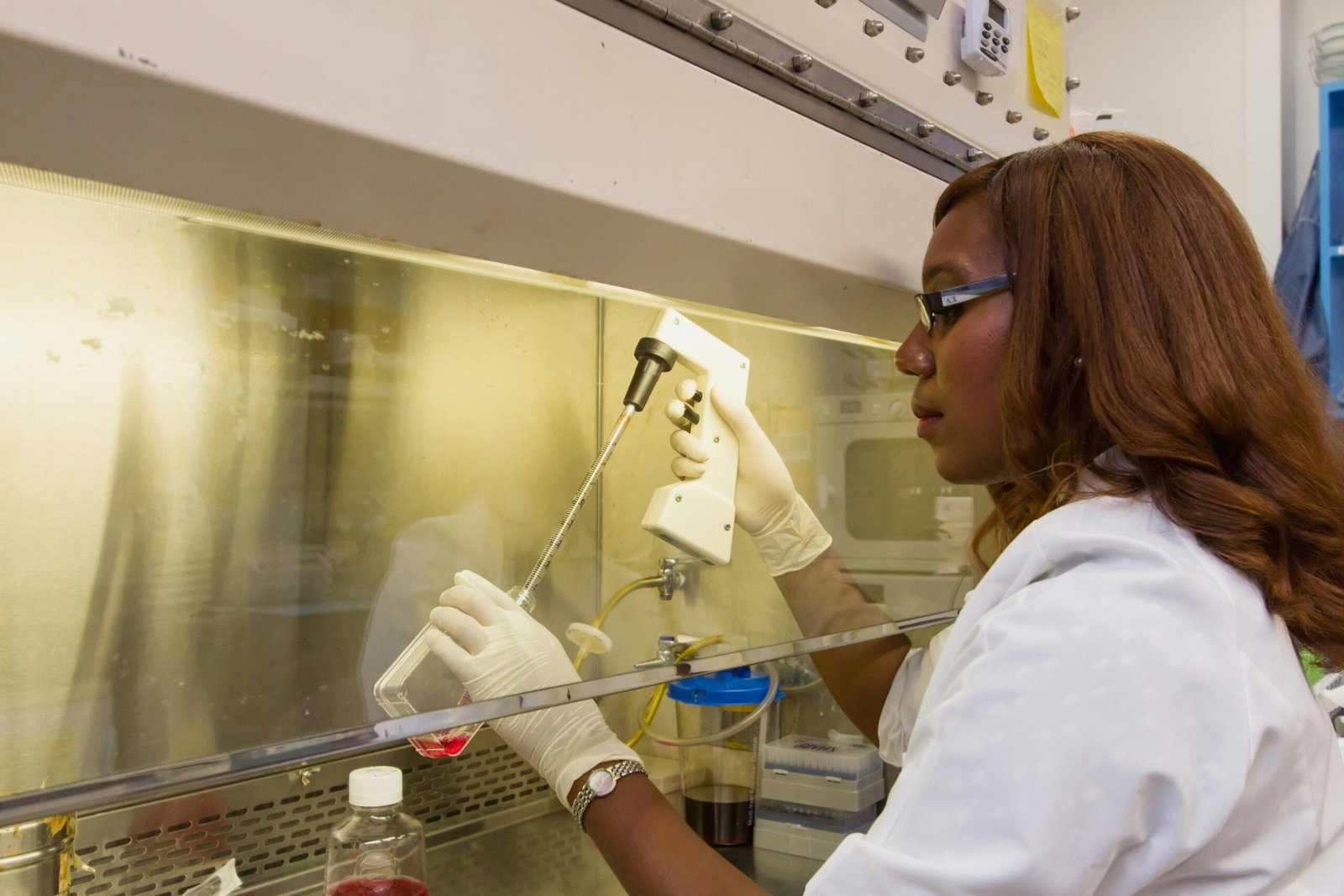

Clean benches are widely utilized in laboratories, manufacturing facilities, and other settings where maintaining a clean work area is paramount. In the realm of scientific research, clean benches are indispensable for procedures that require aseptic conditions, such as cell culture and microbiological experiments. The laminar flow of air prevents contaminants from settling on the work surface, thus safeguarding the integrity of the samples and processes.

In manufacturing environments, clean benches play a pivotal role in the production of sensitive components, particularly in the pharmaceutical, electronics, and aerospace industries. These benches provide a controlled environment that minimizes the risk of contamination during the assembly and inspection of intricate parts. By ensuring a sterile workspace, clean benches contribute to the overall quality and reliability of the final product.

Moreover, clean benches are available in two primary configurations: horizontal and vertical laminar flow. Horizontal laminar flow benches direct filtered air horizontally across the work surface, while vertical laminar flow benches direct air downward. The choice between these configurations depends on the specific application and the nature of the work being conducted. Both types, however, serve the fundamental purpose of creating a contamination-free environment.

In summary, clean benches are indispensable tools in environments where maintaining a contamination-free workspace is critical. By ensuring a sterile and controlled environment, they protect samples, processes, and materials from particulate contamination, thereby enhancing the accuracy and reliability of various scientific and industrial tasks.

How to Specify a Clean Bench

Choosing the right clean bench for your laboratory is crucial for ensuring optimal performance and maintaining the necessary level of cleanliness. The first step in specifying a clean bench is determining the type of filtration required. There are two primary types of filters: High-Efficiency Particulate Air (HEPA) filters and Ultra-Low Penetration Air (ULPA) filters. HEPA filters are typically sufficient for most applications, trapping 99.97% of particles as small as 0.3 microns. However, for environments that demand a higher level of cleanliness, ULPA filters, which capture 99.999% of particles down to 0.12 microns, may be necessary.

Next, you must decide between vertical or horizontal airflow. Vertical airflow clean benches direct filtered air from the top to the work surface, reducing the risk of cross-contamination and providing a more uniform flow across the working area. Horizontal airflow clean benches, on the other hand, push air from the back of the bench towards the operator, which can be more suitable for specific applications and space constraints. Your choice will depend on the nature of your work and the layout of your laboratory.

The size of the clean bench is another critical consideration. Ensure that the chosen bench fits comfortably within your laboratory space while providing sufficient workspace to accommodate your tasks. Measure the available space and consider the dimensions of the bench and any equipment that will be used on it.

Additional features can enhance the functionality and convenience of your clean bench. UV lights for sterilization, adjustable fan speeds for controlling airflow, and ergonomic designs to reduce operator fatigue are all options worth considering. These features can improve the efficiency and safety of your work processes.

Finally, ensure that the clean bench complies with relevant industry standards and regulations. This includes adherence to ISO standards, which specify the requirements for cleanroom environments, as well as any other regulations pertinent to your field of work. Compliance ensures that your clean bench will provide the necessary level of protection and performance required for your application.

Differences Between a Biosafety Cabinet (BSC) and a Clean Bench

Both clean benches and biosafety cabinets (BSCs) play pivotal roles in maintaining contamination-free environments in various laboratory settings. However, their functionalities and safety features are distinct, catering to different requirements. A clean bench, for instance, is designed to protect the work and materials from contamination by providing a unidirectional HEPA-filtered airflow across the work surface. This ensures that any particulate matter is kept away from the materials being handled. However, it is crucial to note that clean benches do not offer protection to the user or the surrounding environment from hazardous materials. This makes them suitable for non-hazardous tasks such as media preparation, plant tissue culture, and electronic assembly.

On the other hand, biosafety cabinets (BSCs) are engineered to provide both product and personnel protection. They are specifically designed to handle biohazardous materials and are equipped with advanced safety features. One of the primary features of a BSC is the negative pressure environment within the cabinet, which prevents contaminants from escaping into the laboratory. Additionally, BSCs are fitted with exhaust systems that filter and remove hazardous substances, ensuring a safe workspace for the user and the environment. This dual protection makes BSCs indispensable in microbiological work, pharmaceutical research, and clinical diagnostics, where the risk of exposure to harmful pathogens is high.

Understanding the differences between clean benches and biosafety cabinets is crucial for selecting the appropriate equipment for your specific laboratory needs. While clean benches are ideal for tasks where user and environmental protection are not a concern, BSCs are essential for applications involving hazardous or biohazardous materials. Making an informed choice not only ensures the safety of personnel but also maintains the integrity of the work being performed.

Applications and Differences Between Vertical and Horizontal Laminar Flow Clean Benches

Laminar flow clean benches are essential tools in maintaining a controlled environment by directing filtered air in a uniform direction. These benches are typically categorized into vertical and horizontal types based on the direction of airflow, each serving distinct purposes and applications.

Vertical laminar flow clean benches direct filtered air downwards from the top of the bench. This downward flow helps to prevent contaminants from settling into the work area, providing a higher level of protection for sensitive processes. Applications for vertical clean benches often involve handling hazardous materials, biological samples, or any process where contamination control is critical. The downward airflow effectively sweeps contaminants away from the work surface, ensuring a sterile environment.

In contrast, horizontal laminar flow clean benches direct air from the back of the bench towards the user. This configuration offers a clearer view and easier access to the work area, making it ideal for tasks where user protection is not a primary concern. These benches are commonly used in applications such as electronics assembly, non-hazardous pharmaceutical preparations, and other processes requiring a clean environment but not necessarily a sterile one. The horizontal airflow helps in keeping the workspace free from particulates without compromising visibility and accessibility.

Sanqiao, a recognized manufacturer of clean benches, emphasizes the simplicity and safety of their products. Their designs cater to a variety of industries with diverse requirements, ensuring that whether it is a vertical or horizontal laminar flow clean bench, users can operate them with ease and confidence. The choice between vertical and horizontal laminar flow clean benches ultimately depends on the specific needs of the application, with each type offering unique advantages in maintaining a clean and controlled environment.

Contact us to get Clean Bench factory price