- ISO Certified 9001:2015

- One -stop customization solution for cleaning room

Descriptions of the functions of Fan Filter Units (FFU):

1. **Air Filtration**: FFU are designed to draw air through high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters, effectively removing airborne particles to maintain cleanroom cleanliness standards.

2. **Airflow Control**: They regulate the airflow within cleanrooms, ensuring consistent and uniform distribution of filtered air to minimize contamination and maintain specified cleanliness levels.

3. **Noise Reduction**: Modern FFU are engineered to operate quietly, minimizing noise pollution in cleanroom environments while maintaining efficient air filtration.

4. **Energy Efficiency**: Advanced FFU designs incorporate energy-efficient motors and airflow control mechanisms to optimize energy consumption, contributing to sustainable operations within cleanroom facilities.

5. **Versatility**: FFUs can be configured for various cleanroom sizes and classifications, accommodating specific airflow requirements and space constraints while meeting industry standards for cleanliness and particle control.

These functions collectively enable Fan Filter Units to play a crucial role in preserving the integrity of cleanroom environments across industries such as semiconductor manufacturing, biotechnology, pharmaceuticals, and aerospace.

A Fan Filter Unit (FFU) is a critical component in cleanroom environments, serving to maintain air cleanliness by filtering out contaminants. Typically installed in the ceiling grid, FFUs draw air through a HEPA or ULPA filter, ensuring a high level of particle removal efficiency. This process helps achieve and maintain the required cleanliness level within the cleanroom, crucial for industries such as pharmaceuticals, electronics manufacturing, and biotechnology.

For requiring customized FFUs in bulk, we factories offer tailored solutions to meet specific cleanroom specifications and operational needs. Customization options include variations in size, airflow capacity, filtration efficiency, and control features. Bulk purchasing options cater to facilities looking to outfit new cleanrooms or upgrade existing ones efficiently and cost-effectively.

The versatility and reliability of FFUs make them indispensable in maintaining the stringent cleanliness standards necessary for sensitive manufacturing processes, ensuring optimal performance and product quality in controlled environments.

Material of air chamber

Galvalume steel / Aluminum alloy / Stainless steel plate (304).

The introduction of fan filter unit (FFU)

The fan filter unit is a self-powered terminal air supply device with filtering function, the fan sucks in air from the top and filters it through the HEPA filter in order to create clean air and evenly send out from the air outlet, it provides stable and strict air environment control for cleanrooms. The fan filter unit can be connected in modules to meet the needs of different enterprises and scientific research for different clean environments.

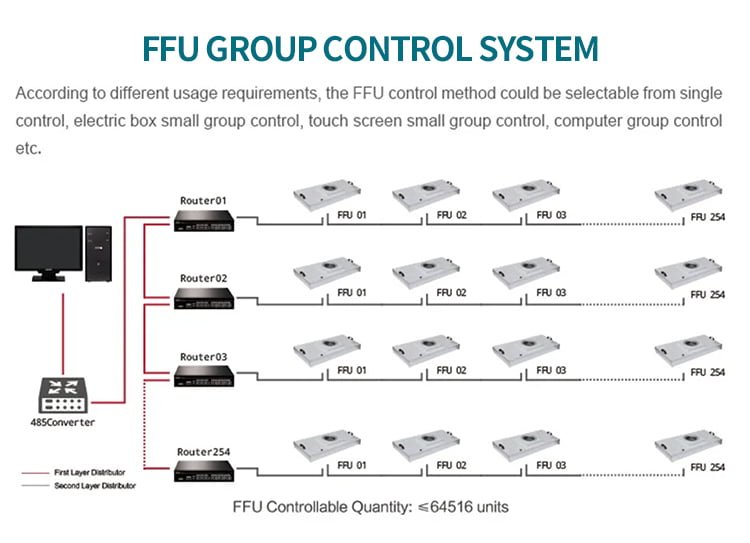

FFU GROUP CONTROL SYSTEM

According to diferent usage requirements, the FFU control method could be selectable from single control, electric box small group control, touch screen small group control, computer group control etc.

Customized product display

OEM, OEM Production services.

Independent R&D team, one-stop solution for cleanroom projects.

THE CLEANROOM EQUIPMENT