- ISO Certified 9001:2015

- One -stop customization solution for cleaning room

Factory Wholesale Price Static Pass Box

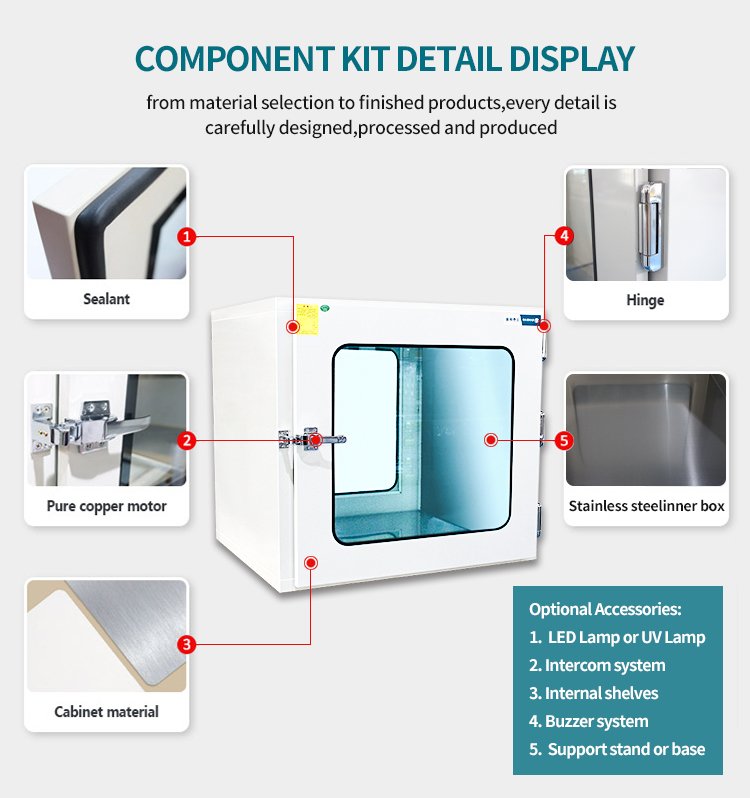

Features:

1. The working area adopts arc transition to avoid cleaning dead corners;

2. The doors on both sides adopt magnetic interlocking or mechanical interlocking to avoid opening the doors on both sides at the same time, causing convection pollution between clean rooms.

3. The electromagnetic interlock adopts an electromagnetic lock with a tensile force of 60kA, and the touch switch controls the power supply, door opening, and ultraviolet sterilization

4. An ultraviolet sterilization lamp or ozone generator can be installed inside, and the equipment has its own sterilization function:

5. The material can be made of high-quality SUS304 or cold-rolled plate paint or SUS201, etc.

6. The door body with special structure is fixed with single-layer glass customized profile, which is convenient for replacement.

7. Equipped with food-grade silicone sealing strips to ensure that the equipment is sturdy and durable and meets GMP standards.

Cleanroom Pass Throughs – Stainless Steel – Mechanical Interlock – Mounting Trim Kit

The cleanroom pass through is for transferring of parts and equipment in and out of a cleanroom or controlled environment. They reduce the need for people to enter the cleanroom. The pass through is available in polypropylene or stainless steel construction. The polypropylene pass thru is constructed of 1/2″ material and a good choice for use around chemicals. The stainless steel pass thru features a welded type 304 shell, stainless steel continuous hinge, tempered safety glass viewing window, silicon bulb gasket, stainless steel lever and compression door latch. Options available on the pass throughs include: mechanical door interlocks, mounting frame, Lexan window, non-outgassing, and HEPA filtered models.

All sizes and styles can be customized | ||

Product model | external diameter (mm) | internal diameter (mm) |

W400 | 400*400*400 | 240*340*320 |

W500 | 500*500*500 | 340*440*420 |

W600 | 600*600*600 | 440*540*520 |

W700 | 700*700*700 | 540*640*620 |

W800 | 800*800*800 | 640*740*720 |

N400 | 560*460*480 | 400*400*400 |

N500 | 660*560*580 | 500*500*500 |

N600 | 760*660*680 | 600*600*600 |

N700 | 860*760*780 | 700*700*700 |

N800 | 960*860*880 | 800*800*800 |

Features:

1. Arc transition is adopted in the working area to avoid dead cleaning;

2. Magnetic interlocking or mechanical interlocking is adopted for both side doors to avoid that the doors on both sides are opened at the same time, which will cause convection pollution between clean rooms.

3. Electromagnetic interlock adopts electromagnetic force lock with a pulling force of 60kA. Light touch switch controls power supply, door opening and ultraviolet sterilization

4. Ultraviolet sterilization lamp or ozone generator can be installed inside. The equipment has sterilization function:

5. Materials can be high-quality SUS304 or cold-rolled plate baking varnish or SUS201, etc

6. The door body with special structure is fixed with single-layer glass customized profiles for easy replacement.

7. Equipped with food grade silicone sealing strips to ensure the durability of the equipment and meet GMP standards.

THE CLEANROOM EQUIPMENT