Microelectronics Cleanroom

Microelectronics Cleanroom

Semiconductor and electronics industry are essential in this era as the consumer electronics are becoming the basic necessity for people around the world. Consumer electronics are used every day, commonly in communications, office productivity and also for entertainment purpose. In an electronics manufacturing plant, cleanrooms are fundamental to the production line so that the goods fabricated are of high reliability.

Most of the semiconductor, microelectronics, electronics, automotive industry need cleanrooms that follow ISO 14644-1 or its predecessor, FED-STD-209E cleanroom standards.

- Ceiling: Ceiling Grid System

- Wall Partition: Stud Wall Partition System / “Z” Lock Flush Wall Partition System

* Static Dissipative Steel Skins - Door: Swing Door / Sliding Door

- Lighting: Teardrop Lighting

- Pass Box: Stainless Steel / EG Steel c/w Powder Coat

- Air Shower Unit: Stainless Steel / EG Steel c/w Powder Coat

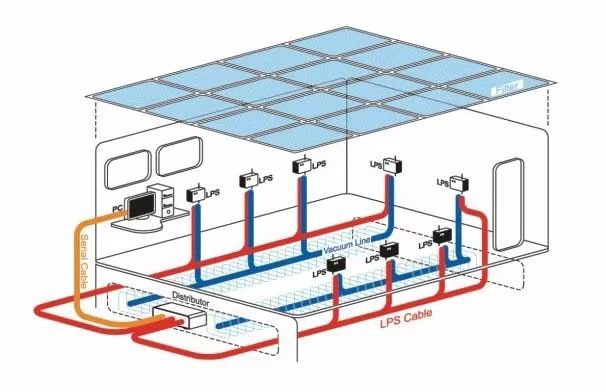

- Filtration: HEPA Filter / ULPA Filter / Fan Filter Unit

- Raised Floor: Aluminium Raised Floor System

- Granularity counting: The requirements for finished wafers reaches the level of 10 million, and the particle count must be controlled below 10,000 per cubic meter

- Air flow velocity: The air flow rate must be controlled at 0.25 ~ 0.45m/s

- Number of air replacement times: Generally requires air ventilation times 10-15 times per hour

- Ionizing radiation: ionizing radiation requirement reaches 10 micro -Xi ABove

- Temperature and humidity: The temperature in the laboratory is controlled between 18 and 25 ° C, and the humidity is controlled between 20%and 60%